Tool development & construction

Each system is only as strong as the single part

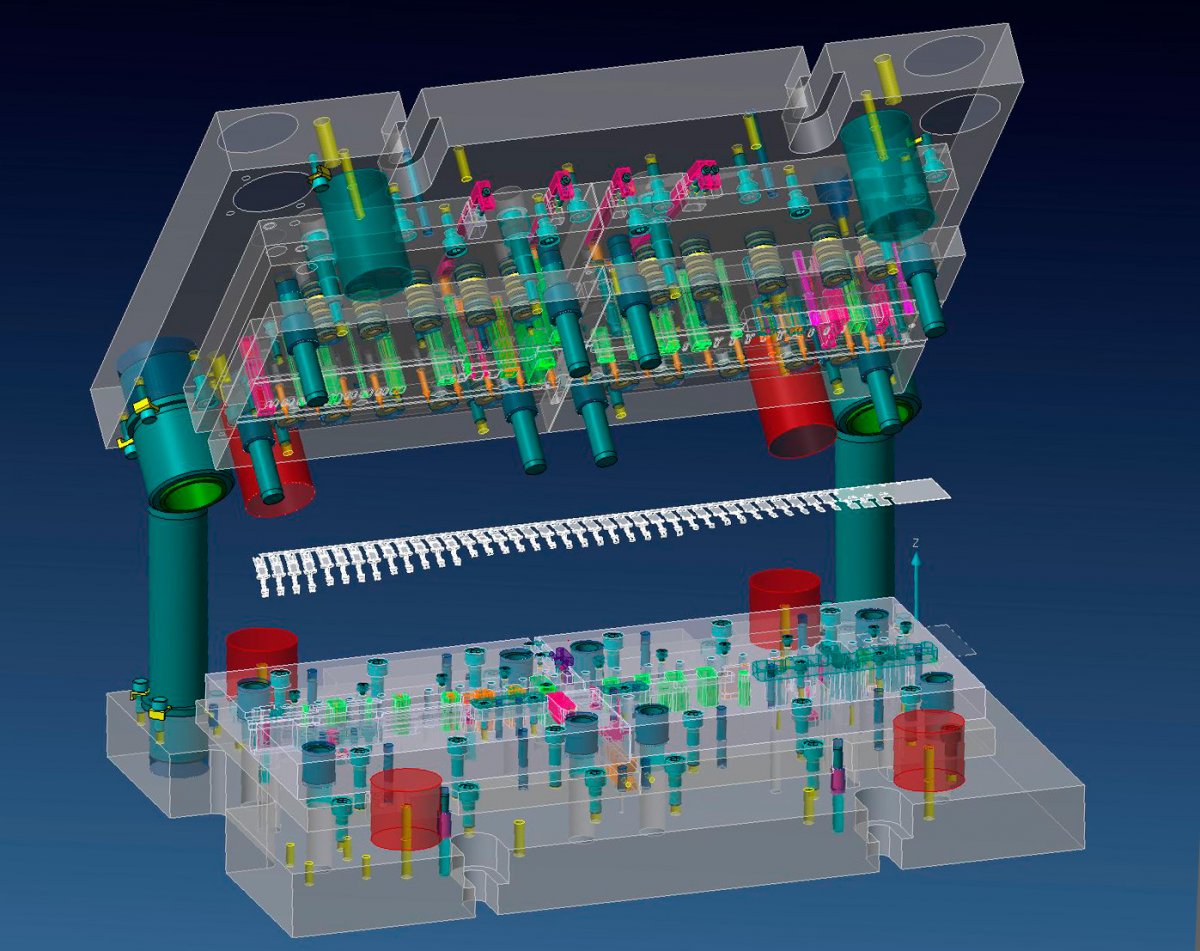

Tool concept

Because we have proven ourselves here, we know what is important to our customers. Sometimes we may even think of the last step before taking the first move. By understanding our customers and their special challenges in specific markets, we can anticipate solutions to potential problems. But: in order to test a new design or a process in a maximum near-series execution, we prefer to think long term. We have been challenged several times. By now, we know exactly what is important to our customers. After all, your projects should form the future.

That's how it works:

As soon as we have jointly defined the requirements for the serial part, the optimum tool concept is planned. We take into account all available data on quality requirements, total service life, batch sizes - and of course costs.

If necessary, we submit alternative suggestions: from the simplest prototype tool to high-end tools, suitable for high-speed operation with 100% monitoring using the latest sensor technology.

Process-reliable production

In principle, however, we attach the greatest importance to the fact that agreed quality features of the serial part can be manufactured reliably. This is based upon an extensive FMEA, so that our many years of experience is reflected in every new design: as a circle of continuous improvement (CIP) already in the development phase of new tool concepts.

We would also be pleased to support you in the development of the series part – if the function and requirements are known, we advise you on the stamping feasibility and cost-effectiveness.

Data exchange

Data exchange with all common file formats.

For this purpose our CAD/CAM system has

various interfaces

- CAD/CAM System from VISI

- Data exchange with all common file formats such as STEP, IGES, DXF, DWG, Parasolid, etc.